The turning of a rotor is the process of rotating a shaft with a fixed number of teeth in order to give it a circular motion.

Rotor generators are usually used to generate power for industrial purposes or for emergency backup systems in hospitals and other places where critical electrical needs must be met.

There are two types of rotors, direct-drive, and geared-drive. Direct-drive rotors use an armature to turn the shaft while geared drive uses a gear train that transfers power from the motor to the rotor blade(s).

To produce more energy, turbines use larger rotors with more blades (i.e. greater rotation speed) which results in increased output of electricity generated per unit of inputted energy.

Turbines can be classified according to their type of fuel: gas, diesel, oil or steam turbines.

A gas turbine converts natural gas into mechanical energy by burning it with oxygen at high temperatures; whereas a diesel engine burns fossil fuels like gasoline or coal to create heat and motion – hence its name – before combustion takes place inside the engine block.

Contents

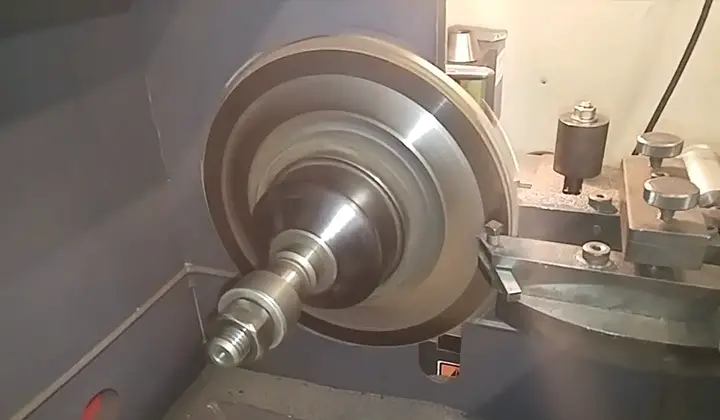

What Is Turning a Rotor

Rotors are typically used to generate power by spinning a shaft that is connected to an electric motor or generator. They can also be used as fans and blowers, pumps, compressors, and turbines. Rotors can also be found in the form of a drill bit or screw thread.

When replacing a rotor, always make sure to use the correct type (size) for your appliance and install it correctly according to the manufacturer’s instructions.

If your appliance has been abused or is not operating at its best because of a defective rotor, it may need to be replaced entirely.

Be careful when removing old rotors; they can easily snap off if mishandled so handle them with care.

Cleaning a rotor will help ensure longevity by preventing the build-up of dust and lint which could cause problems down the road.

Always follow the manufacturer’s instructions when installing new rotors – failure to do so could result in serious injury.

When to Turn the Rotors

If your car is having trouble turning, there are a few things you can do to try and fix the issue.

First, check to see if the rotors are damaged or worn out. If they are, you’ll need to replace them.

Second, make sure that the brakes are working properly by pressing down on the pedal and checking for any noise or vibration.

Finally, inspect the fluid levels in each of your brake pads and discs (if applicable).

Vehicle Won’t Start

If your vehicle won’t start, it could be due to a number of different reasons, but one of the most common is that the rotors are not turning properly.

When the rotors aren’t spinning fast enough, they can cause excessive noise and vibration in the engine. This problem can also lead to poor fuel efficiency and decreased performance.

Shifting Issues

If you have issues with your car shifting gears, there may be something wrong with the rotors or rotor bearings. If too much heat builds up on these parts over time, it can cause them to fail altogether.

In some cases, this issue may also result in serious damage to other components in your car – so make sure you take care of your rotors.

Excessive Noise

When the rotors aren’t turning quickly enough or they become damaged in some way, they will create an excessive amount of noise when grinding against each other – which will then be transmitted into the cabin through the speakers.

FAQs

Is Turning Brake Rotors Necessary?

In some cases, yes, as the friction created by the spinning rotor can cause heat buildup which can lead to a fire.

Is Resurfacing Rotors the Same as Turning Them?

Resurfacing rotors is the process of removing a layer of metal from a rotor blade and then installing a new one on top of it. Turning rotors is the act of rotating the blade to change its direction or speed.

How Long Does Turning Rotors Last?

A typical turning rotor has a lifespan of between 30,000 and 70,000 miles.

What Happens if You Replace Brake Pads Without Turning the Rotors?

If you decide to replace your brake pads without turning the rotors, be aware that this will cause a lot of problems with your braking system. You should replace them both together so that they work properly and safely.

How Much Does It Cost to Turn Rotors?

The cost of turning a rotor can vary depending on the size of the machine and the type of material it’s made out of but typically it costs $15 to $25 for each rotor.

How Often Should Rotors Be Replaced?

The frequency of rotor replacement is typically dictated by the type of rotor and the amount of use.

For example, a rotor for a windmill typically needs to be replaced every 10 years, while a rotor for a helicopter typically needs to be replaced every five years.

Can I Just Replace Front Rotors?

The answer is no. Replacing the front rotors on your car is a big job that requires special tools and expertise.

Final Words

If you are seeing warning signs that your rotor might be about to go, it is important to take action. A failing rotor can cause the car’s engine to stop working and may require expensive repairs.

Here are some common warning signs and what you can do if they occur.

There is nothing that you can do to fix a faulty rotor. Rotors are usually replaced as part of a regular tune-up or maintenance schedule.

A rotor will occasionally seize up, which will cause your car to stop working. When this happens, the only option is to replace the entire rotor assembly.

Rotors are typically used to generate power by spinning a shaft that is connected to an electric motor or generator.

They can also be used as fans and blowers, pumps, compressors, and turbines. Rotors can also be found in the form of a drill bit or screw thread.