If you have drilled and slotted rotors on your car, you may be able to resurface them yourself using a few simple tools. Drilled and slotted rotors can be resurfaced using a standard drill bit, but it is important to use the correct size bit for the job.

Slotted rotors are generally resurfaced with a 3/8 inch (9 mm) bit while drilled rotors require a 1/4 inch (6 mm) or larger hole. You will need a drill, some sandpaper or an emery board, and a slotting tool.

First, make sure that the rotor is clean and free of any rust or other debris particles.

Then use the drill to create holes in the center of each hole on the rotor. Now use the slotting tool to cut slots into each hole.

Finally, sand down both sides of each slot with moderate pressure until they are smooth.

Contents

Can You Resurface Drilled and Slotted Rotors?

If your car has drilled and slotted rotors, you may be able to resurface them yourself. Drilled slots are shallow holes that allow the rotor to turn more easily.

Over time, these small holes can become clogged with brake dust and other debris.

By resurfacing the rotors, you can restore their original performance and minimize the chances of future problems.

There are several steps you can take to resurface them yourself:

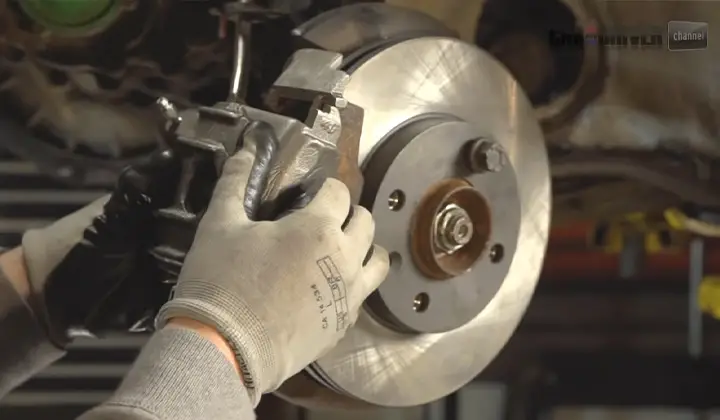

Remove Brake Pads

Before you can resurface drilled and slotted rotors, it is important to remove the brake pads. This will allow you to safely work on the rotor without any interference from the brakes.

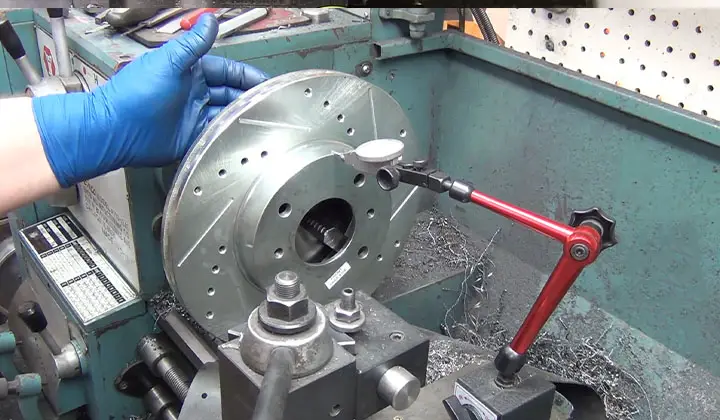

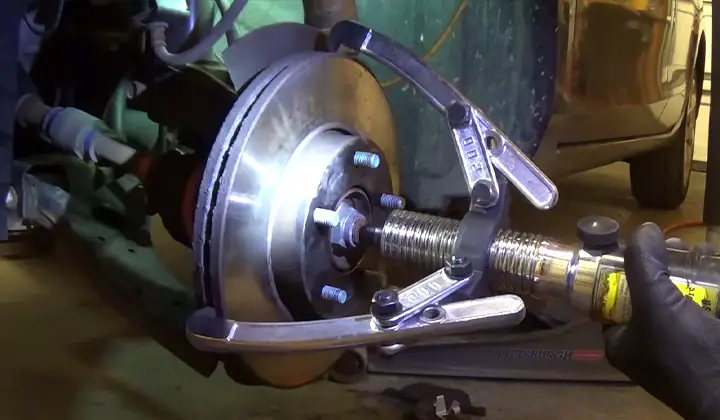

Remove the Rotors from the Wheel

Make sure you keep track of which side is which so that you can re-install it properly in reverse order later on.

Clean Rotor Surface

Once the brake pads are removed, it is time to clean off the surface of the rotor with a degreaser or a cleaner designed for this purpose. Make sure to remove all traces of rust, oil, and grease before proceeding further.

Apply Resurfacing Material

Now that your rotor has been cleaned and prepared, apply a resurfacing material such as chrome-plated steel or silicon carbide sheeting in a uniform manner using perforated discs or sandpaper disks attached to an orbital sander.

Be sure not to overheat or damage your rotor while applying the material; use moderate pressure and avoid working on wet surfaces.

Clean all exposed surfaces with brake cleaner or a degreaser. Pay particular attention to any grooves or slots in the surface where the pads meet the disk.

Finish Up with Care

Apply a thin layer of braking compound to each hole in the rotor using an applicator brush or rag (a toothbrush will also work).

Be careful not to overtighten your hands as this can cause damage. Let dry completely before reinstalling onto the wheel.

Benefits of Resurfacing Drilled and Slotted Rotors

Drilled and slotted rotors are a type of rotor that is used on cars. They were first invented in the early 1900s but didn’t become popular until the 1970s.

Drilled and slots are two different types of slots – drilled slots have holes while slots have ridges.

Slotted rotors can be resurfaced by drilling new holes or removing the ridges, depending on your car’s needs.

There are a few benefits to resurfacing drilled and slotted rotors, including:

Improved Braking Performance

Re resurfacing drilled and slotted rotors can improve braking performance by increasing the friction between the pads and the rotor surface. This will result in longer rotor life, which will reduce noise levels.

Longer Rotor Life

The wear on a rotor is usually proportional to its diameter. Re resurfacing a drill or slotted rotor results in increased pad life due to improved braking performance as well as reduced noise levels generated from brake pads rubbing against the rotors

Reduced Noise

When your rotors are resurfaced, the metal is ground down to a very thin layer and then coated with a new type of material called an anti-corrosion coating.

This process effectively reduces noise from the rotor by eliminating any rattles or creaks that may occur.

If your drilled and slotted rotors are showing signs of wear, it may be time to resurface them.

Drilled and slot rotor systems offer increased braking performance in wet or icy conditions, but they can also become damaged over time. By resurfacing the rotors, you can restore their braking ability and keep your car safe on the road.

FAQs

Can You Turn Drilled Slotted Rotors?

The answer is, yes you can.

Drilled slotted rotors are designed for high-performance braking in extreme conditions. They are designed to be used on the track or for your daily driver.

Why Are Drilled and Slotted Rotors Bad?

Drilled and slotted rotors are bad because they can cause a lot of problems. They are bad because they can cause cracks in the rotor and even lead to total failure.

The drilled holes in the rotor also create stress risers which can also lead to cracking.

Slotted rotors are designed to improve cooling, but they do this by allowing water to get inside the brake pads. This causes corrosion and rust that will eventually lead to a total failure of the brake pads.

How Long Do Drill and Slotted Rotors Last?

It is difficult to accurately predict how long a drilled and slotted rotor will last.

There are many factors that can affect the life of a drilled and slotted rotor, including the type of drilling, the number of slots, the thickness and material of the rotor blades, and whether they are used in a wet or dry environment.

Do Slotted Rotors Need to Be Resurfaced?

Slotted rotors require a lot of maintenance, which is why they need to be resurfaced.

Where Can I Turn in Drilled and Slotted Rotors?

If you need help finding a service center for your drilled and slotted rotors, you can try one of these places:

* Toyota dealership

* Ford dealership

* Honda dealership

* Nissan dealership

Conclusion

In conclusion, you can resurface your rotors by using a rotor resurfacing kit. This will help to restore the braking performance of your car while protecting it from future damage.

Drilled and slotted rotors are designed for use on vehicles with disc brakes, which means that they can handle the wear and tear of daily driving.

So, whether you’re looking to save money or just give your car a new lease on life, consider resurfacing your rotors.